I had the chance to attend a dairy farm tour recently, at Barstow’s Longview Farm, a 7th generation family farm in Hadley, Massachusetts.

If you’ve never done a farm tour before, I highly recommend it! Much like my recent tour of The Country Hen, I learned so much about how the animals are cared for, what it takes to keep up a working farm, and so much about where our everyday food comes from.

What’s the first thing you think of when you hear dairy farm tour?

Adorable baby cows with giant soulful eyes? Check.

Close encounters with velvety soft pink noses? Oh yeah.

Close encounters with velvety soft pink noses? Oh yeah.

Photo ops with the ever-present cow statue? Yup, even that.

Photo ops with the ever-present cow statue? Yup, even that.

Mischievous farm dogs, rolling green hills, picturesque silos and barns, and a homey farm store round it all out. Pretty standard farm happenings.

Mischievous farm dogs, rolling green hills, picturesque silos and barns, and a homey farm store round it all out. Pretty standard farm happenings.

What I want to share with you now are a few things that may not come immediately to mind when you think of a dairy farm tour.

Have you ever heard of an anaerobic digester?

Nope? I hadn’t either.  This simple-looking structure is actually a $2 million machine that converts the methane gas from cow manure into heat and electricity for the farm. Soon, it will be providing electricity to the nearby neighborhood, too. This, our tour guide shares, is a great trade-off for having to put up with farm smell for many years.

This simple-looking structure is actually a $2 million machine that converts the methane gas from cow manure into heat and electricity for the farm. Soon, it will be providing electricity to the nearby neighborhood, too. This, our tour guide shares, is a great trade-off for having to put up with farm smell for many years.

It does have a certain pungeant aroma 🙂

What do cranberries have to do with dairy farming?

Calories, calories, calories.

When making milk all day long is your full-time job, you need a lot of energy. The Barstow’s cows average 85 pounds per day of milk production, and are milked two to six times a day.

I can’t even imagine the calories they’re burning.

Cranberries to the rescue. This pile of cranberry pulp is shipped in from southeasten Massachusetts cranberry bogs after the processors have squeezed out the juice. Barstow’s adds the pulp to the cows’ corn/hay mixture to provide additional carbohydrates and energy, as well as that tartness the cows have been asking for 😉

Cranberries to the rescue. This pile of cranberry pulp is shipped in from southeasten Massachusetts cranberry bogs after the processors have squeezed out the juice. Barstow’s adds the pulp to the cows’ corn/hay mixture to provide additional carbohydrates and energy, as well as that tartness the cows have been asking for 😉

What on earth is a robotic milker?

I’m so glad you asked. According to our tour guide, the robotic milker allows them to better monitor each cow’s health by tracking things like her weight, temperature, and milk production levels.

According to our tour guide, the robotic milker allows them to better monitor each cow’s health by tracking things like her weight, temperature, and milk production levels.

The amazing part is, the cows are trained to go the milking machine on their own…! How…???

Snacks. That’s how. The cows are trained to get a snack when they feel udder pressure. Their walk to the snack bucket places them on the platform of the automated milking machine. Using lasers, it locates their teats and maps the udder. The teats are then cleaned and disinfected, and then milked.

All the while, the cow is noshing away. Udderly brilliant 😉

I’d like to thank Barstow’s Longview Farm for hosting me and my interns for an informative tour, and the New England Dairy and Food Council for sponsoring the trip.

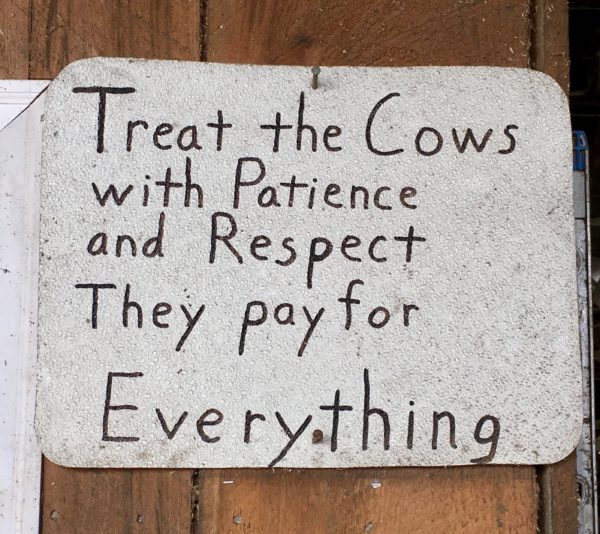

It was a great day of learning about small dairy farming! The Barstow’s crew were informative, welcoming, and funny, and they sure do treat their cows well. And for good reason 🙂

Disclaimer: The New England Dairy and Food Council sponsored this trip for Boston-area dietetic internship programs. They provided transportion, but no compensation. All opinions, errors, and omissions are mine alone.

Leave a Reply